Water Spray Retort/Water Spray Food and Beverage Glass Bottle Retort Sterilization Machine

Basic Info.

| Model NO. | P-1205 |

| Application | Milk, Yogurt, Pet Food, Ready-to-Eat Meals |

| Customized | Customized |

| Heat Exchanger | Spiral-Tube Heat Exchanger |

| Transport Package | Wooden Box |

| Specification | P-1205 |

| Trademark | DTS |

| Origin | China |

| HS Code | 8419899090 |

| Production Capacity | 300 Sets/Year |

Product Description

Product Description

The water spray rotary sterilization retort uses the rotation of the rotating body to make the contents flow in the package. Heat up and cool down by the heat exchanger, so the steam and cooling water will not contaminate the product, and no water treatment chemicals are needed. The process water is sprayed onto the product through the water pump and the nozzles distributed in the retort to achieve the purpose of sterilization. Accurate temperature and pressure control can be suitable for a variety of packaged products.

Certifications

Retort is designed and produced according to the requirements of GB150-2011 <steel pressure vessel manufacturing standard>. DTS is identified and has passed through ISO9001, ISO14001 system authentication and also passed America ASME as well as SGS, TUV, BV, EAC rated.Our Advantages

1. Applicable products: Sterilization of products in aluminum and tinplate cans, glass jars, pouches and trays.

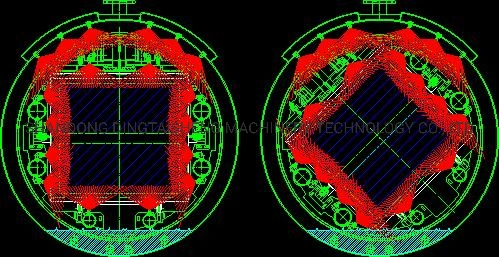

2.DTS patent system: Fixed jets of water rain distributed on the upper part of the retort. While rotary jets of water rain distributed on the crate's walls of the retort.

3. Production advantages:Quality increasing,energy saving; Up to 20% of reduction of total Sterilization time; Considerably less Water and steam consumption.

DTS Technologies

1.Spiral-tube heat exchanger made of stainless steel

Inside tube material is stainless steel 316L, no need to replace the rubber gasket, no need maintenance, corrosion resistance, long service life.2.Full automatic linear control system

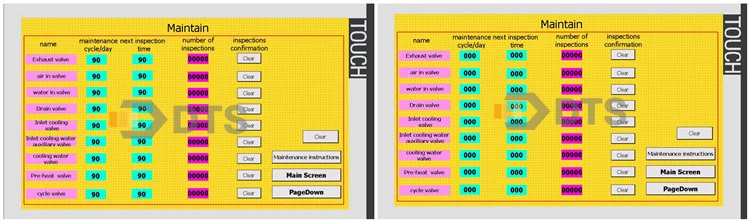

DTS self-studied patented technology D-TOP system can be sensitive to temperature.It can automatically calculate the pressure changes inside the container according to the temperature.And then automatically adjust the pressure inside the retort to get the pressure balance between container internal and external.So it can prevent the package's deformation, keep the package shape.Especially be suitable for aluminum tray products.Pressure was controlled in + / - 0.05 bar with compressed air intake valve and exhaust valve.3. maintence cycle and alarm:For main valves, we set the maintenance cycle and time in the PLC, when it arrives, there will be alarm appear to notice.

Product Parameters

Standard sizes:

1300 mm, corresponding to maximum size of manually operable basket and a capacity from 2 to 4 baskets1500 mm, from 3 to 5 baskets1800 mm, 4 and 6 basketsPacking and Delvery

Project Case

Company Profile

The predecessor of DTS was founded in China in 2001.In the year of 2015 and 2016, we cooperate with Italy Laveti and Gemany Innova.We introduced their technology and produce in China DTS.So we have high quality and lower price.DTS is the most influential supplier of retort equipment in the food and beverage industry in Asia.Our goal is to become the top international brand in food sterilization industry.We have highly experienced and talent mechanical engineers, design engineers and electrical software development engineers.It is our aim and responsibility to provide the best products and services as well as excellent working environment for our customers.We love what we do, and we fully understand that our value lies in helping customers create value.To this end, we are cautious to develop and design various flexible and customized solutions to meet different customer needs through well communication.